|

|

����Q�����u�~�������q |

|

HONG KONG SPRAYING AND MACHINERY INDUSTRIAL CO. LTD.

|

�@

�@

| PRODUCT |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

�@

| HONG KONG OFFICE |

| Address: No 7-8, 11/F Block A, Vigor Industrial Building, 14-20 Cheung Tat Road, Tsing Yi |

| �@ |

| Tel: 24317981 |

| Fax: 24320126 |

| �@ |

| E-mail: sales@hkspraying.com.hk |

| PRODUCT | CONTACT | ���� |

�@

| CLEAN ROOM | �@ |

�@

�@

ISO 14644-1 CLEAN ROOM REQUIREMENT

------------------------------------------------------------------------

�@

| The ISO cleanroom classification standard 14644-1 (implemented in 1999) has replaced the USA FS209E standard and becomes the international clean room standard | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

�@ �@ |

�@ ISO 14644-1 defines a clean room as ��A room in which the number of concentration of airborne particles is controlled and which is constructed and used in a manner to minimize the introduction, generation and retention of particles inside the room and in which other relevant parameters e.g. temperature, humidity and pressure, are controlled as necessary.��

��Cleanrooms can have one or more clean zones, protecting a critical area. The environment for a clean process must not necessarily be a cleanroom but can often be a clean zone in a less clean room. These clean zones can be provided by clean benches, work stations, minienvironments and isolators, the standards of which should also be considered by the designer.��

�@ |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

�@

CLEAN ROOM EQUIPMENT

------------------------------------------------------------------------

�@

| AIR SHOWER & CARGO SHOWER | |||

| �@ |

�@ to blow away dust from workers before entering the spray room to enhance the filtering effect of "Clean Room" �@ |

||

|

�@

�@ |

|

|

|

�@

�@

| FILTERING SYSTEM | |||

|

�@ �@ |

�@ to maintain the clean room in positive pressure so that only clean air will be blown in By use of ��Positive Pressurized Theory��, all outside dirty air can be washed away by 3 layers of filters to ensure only clean air can be supplied into the spray room. �@ |

||

|

|

|

|

|

�@

|

|

|

|

�@

�@

| DE-IONIZING CABINET & DE-IONIZING MACHINE | |||

|

�@ �@ |

�@ to blow away electro-statics and dust by de-ionized blower �@ |

||

|

|

|

|

|

|

|

|

|

|

�@

| CHANGING ROOM | |||

|

�@ �@ |

�@ Workers need to wear protective clothing (hoods, face masks, gloves, boots) before entering clean zones �@ |

||

|

|

|

�@ | |

| �@ | �@ | �@ | |

�@

�@

| LAMINATED PARTITIONS& EPOXY FLOORING | |||

|

�@ �@ |

�@ to reduce electro-statics and dust accumulation �@ |

||

|

|

|

|

|

|

|

|

|

�@

�@

| DUST COLLECTION FOR GRINDING | |||

| �@ | �@ | ||

|

|

|

|

|

| �@ | �@ | �@ | |

�@

�@

| SECONDARY FILTERING SYSTEM | |||

| �@ | �@ | ||

|

|

|

|

| �@ | �@ | �@ | |

�@

�@

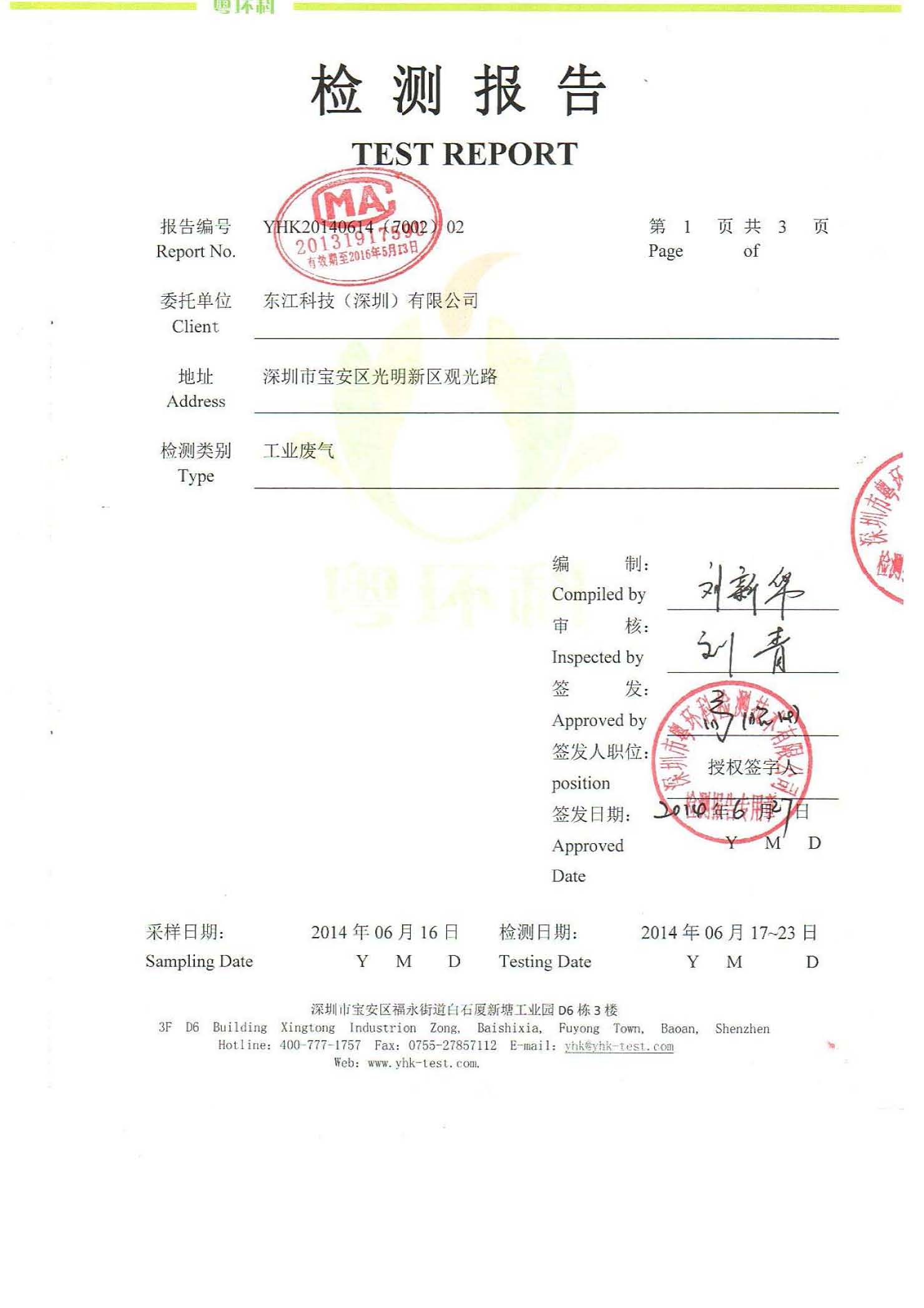

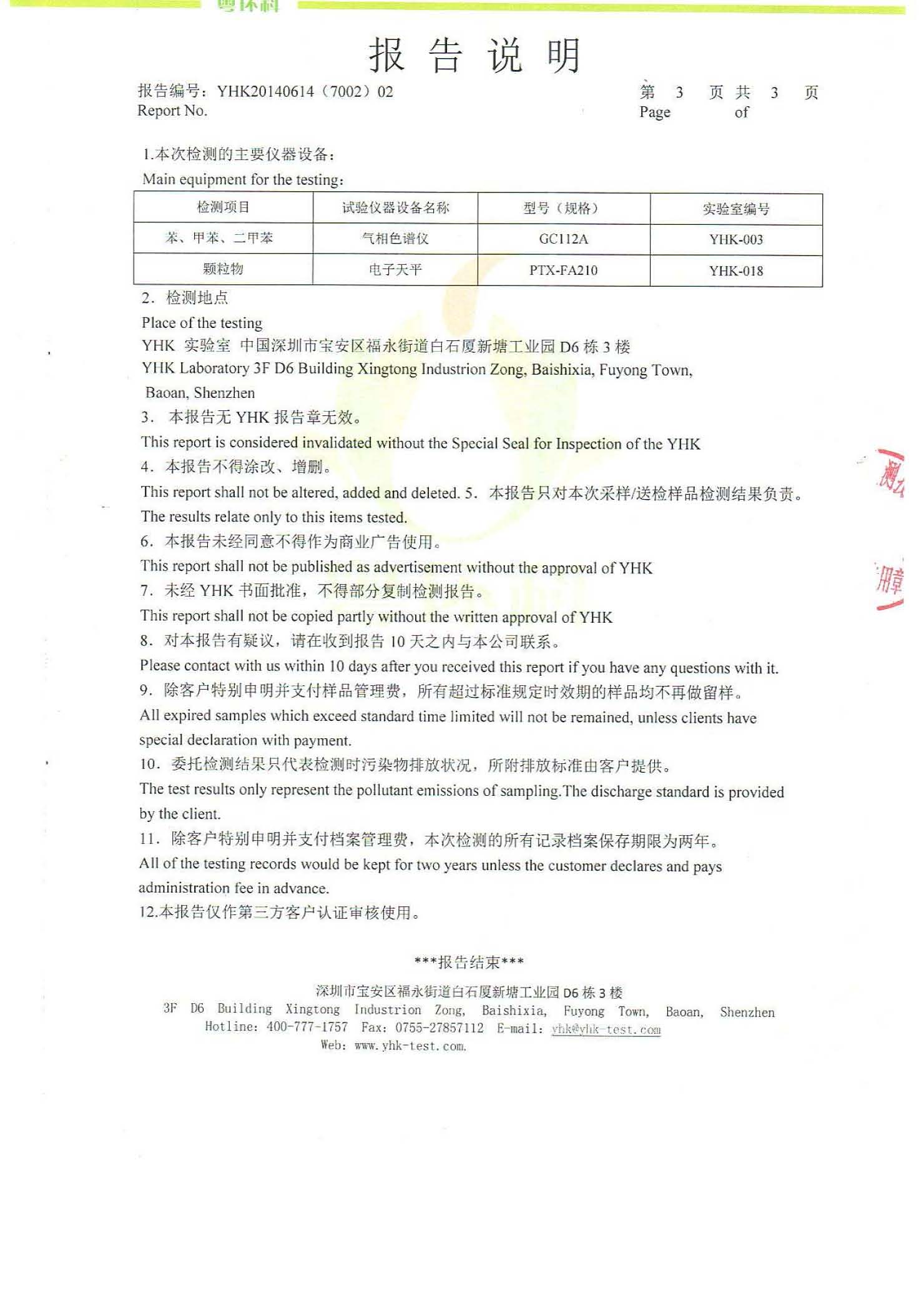

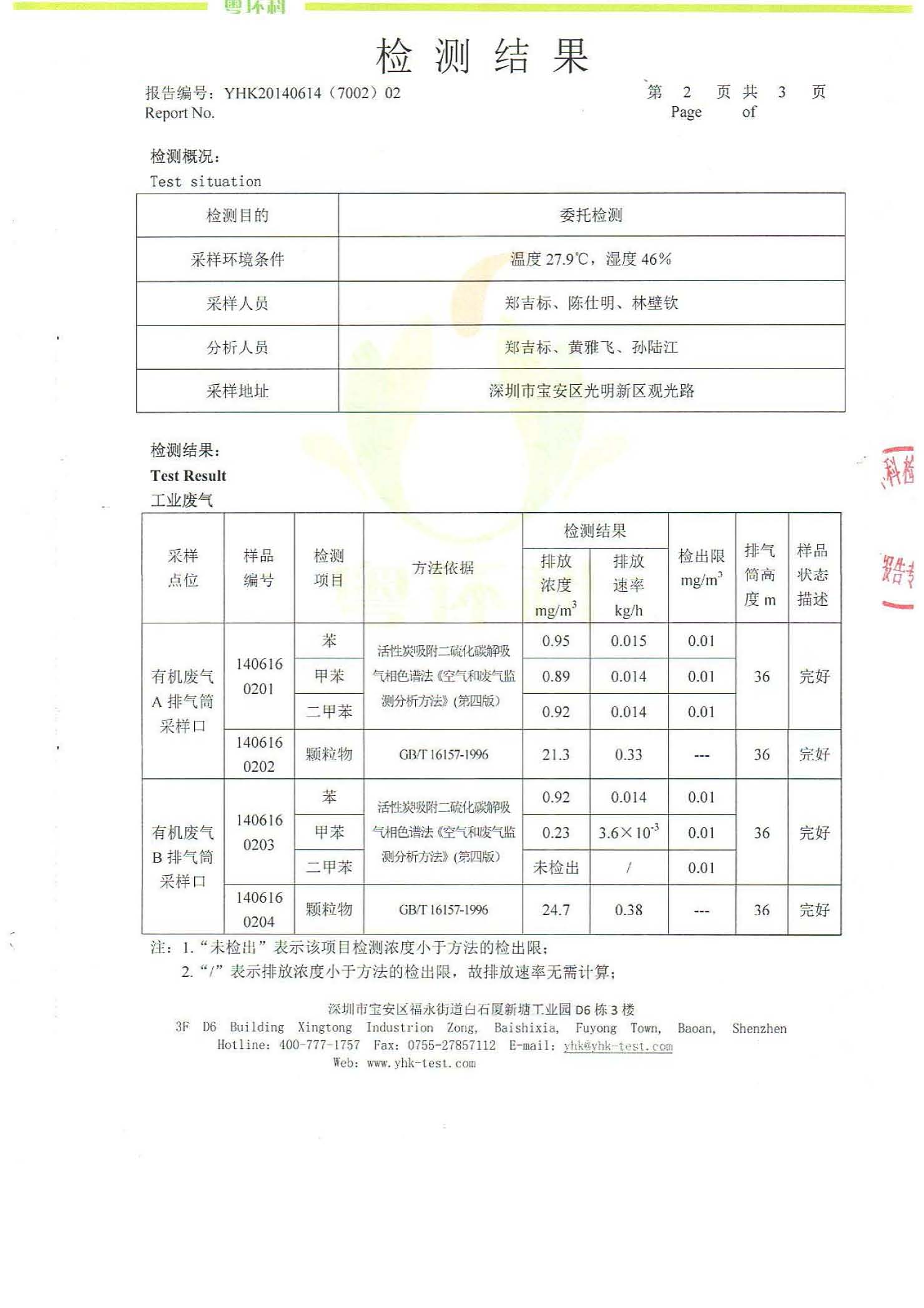

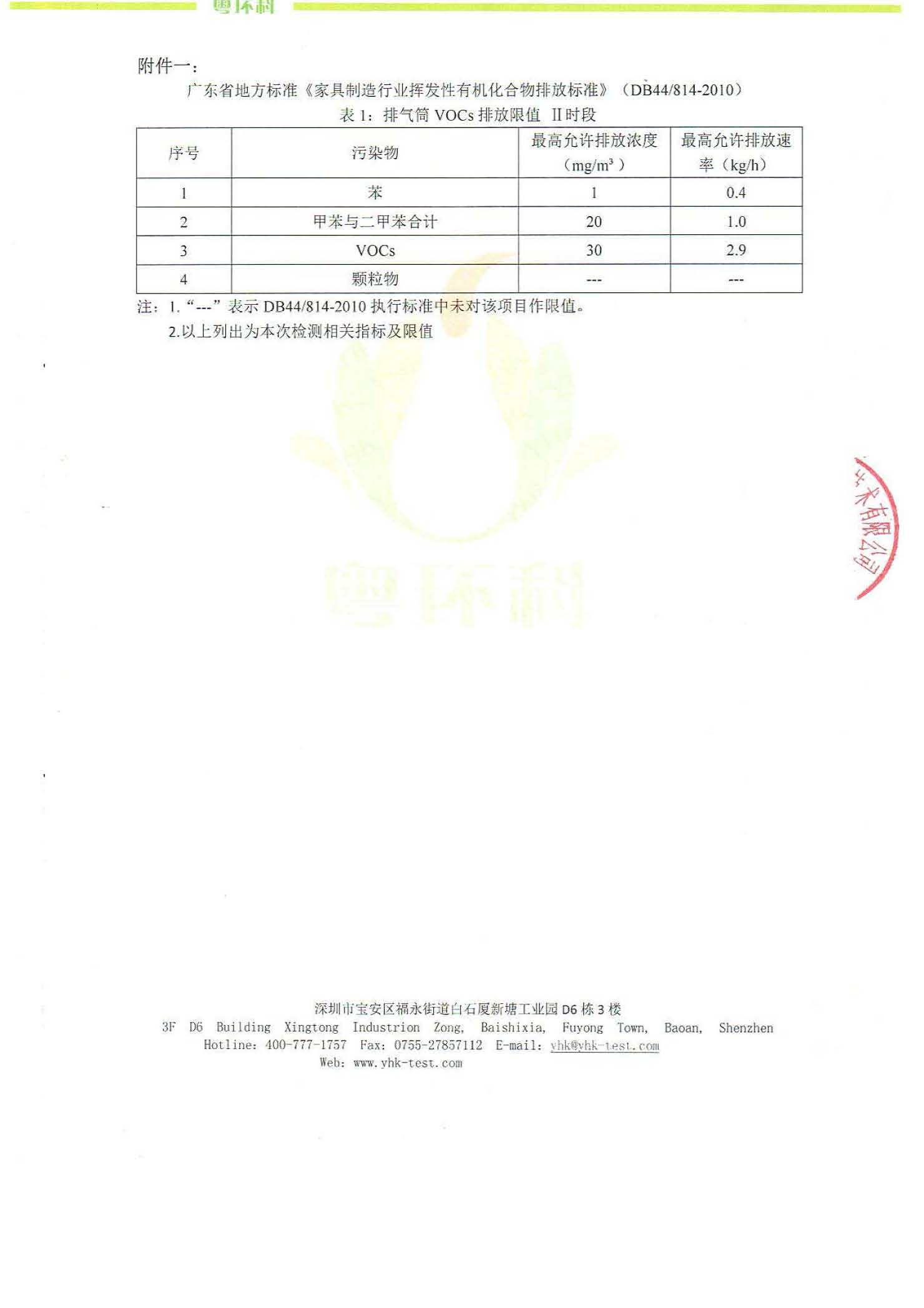

| CLEAN ROOM REPORT: ISO 14644-1 CLASS 10K | |

|

�@ �@ |

|

���۰ʲ���[�Q����

-------------------------------------------------------------------------

�@

| �B�@��z | ||

|

�@ �@ |

�@

���Q�����Q�� "�t�����O"

��z�M�~����,��l�L�Q����P���V�X, ���Ϥ������������� "�s����"

�ĪG�ӹ����M�~���o�o��,���o���d�������,�Q�������Ů�h�ƥX�ǥ~,

�ҥH�����A�X�����c��������[�Q������.

�@ |

|

�@

| �u�I | ||

| �@ | ���Q�����ŦX����Ҥu�B�W�w���o���̰��i�Ʃ�q�з� (OEL), �]�Ӧ�������[�Q���ɫ��w�ϥΪ��Q����. |

|

�@

| �@ | �@ | �@ | �@ |

| �@ �@ |

�@ | �@ | �@ |

�@

�@

�@

�콦�Ϊ��ݲ���[�Q����

-------------------------------------------------------------------------

�@

| �L�o��z | ||||

| �@ |

1. ��ر��ਤ��,

�Q�j�n�\���פμQ�����Ƨ��i�ۥѽծ�, �O���������� 2. �����ĥΤ����s�y 3. �t�Ʀ۰ʮ�Q�j, �Ͳ��IJv��, �C�p�ɲ��q�F 80 ����� 4. �i�Q��Ӥp�����콦�s��ο��� �@ |

|||

|

�@ |

|

|

|

|

�@

�@

�@

���ݲ���[�Q����

-------------------------------------------------------------------------

�@

| �u�I | |

| �@ |

1. ��ر��ਤ�ץi�ۥѽծ�, �Q�j�n�\���פμQ�����Ƨ��i�ۥѽծ�, �O���������� �@ 2 . �i��Φ۰ʮ�Q���j�Φ۰��R�q�Q���j, �Ͳ��IJv��, �C�p�ɲ��q�F 80 ������@ 3. �i�Q��Ӥp�����콦�s��ο���

|

| �@ �@ |

|

|

|

| �@ �@ |

�@

|

�@ | �@ |

�@

�@

����[�y����

-------------------------------------------------------------------------

| �@ �@ |

�@ 1. ����[�Q����J�K�l�e����y����������H�O����ح��o�����ƫG�R 2. �i�P���\�� 10 ����� 3. �j�ਤ��, ��V�ήɶ����i�ۥѽծ� �@ |

�@

| �@ | �@ | �@ | �@ |

| �@ | �@ | �@ | �@ |

| �@ | �@ | �@ | �@ |

| �@ | �@ | �@ | �@ |

| �@ | �@ | �@ | �@ |

| �@ | �@ | �@ | �@ |

| �@ | �@ | �@ | �@ |

| �@ | �@ | �@ | �@ |

| �@ | �@ �@ �@ |

�@ | �@ |

�@

�@

�@

�@

�@

�o����ղŦX�^��,����Τ����a�з�

-------------------------------------------------------------------------

�@

| �^�� OES �з� | |

| �@ |

�@ 1. �Ĥ@�Ӽo��˥��t�зǼQ�@��� 2. �ĤG�Ӽo��˥��ߨ������Q�@��� |

|

COMPONENT VOC |

OES Limit | Sampling with standard Water-Wash Spray Booth (Shenzhen: 7/1/98) |

Sampling with Specially made Water-Wash Spray Booth (Chek Lap Kok:30/7/98) |

|

Isopropyl alcohol �@ |

400ppm | <0.1ppm | <0.1ppm |

|

n-butyl alcohol �@ |

50ppm | <0.1ppm | <0.1ppm |

|

Ethanol �@ |

200ppm �@ |

0.5ppm �@ |

<0.1ppm |

| Methylethyl ketone | 1000ppm | 6.8ppm | 2.8ppm |

| Phosphoric acid | 1mg/m3 | 0.2mg/m3 | <0.05mg/m3 |

�@

Conclusion

The concentrations of five different parameters in the paint mist were measured at Shenzhen (7-1-98) and Chek Lap Kok (30-7-98) respectively and the results are presented. It is concluded that the VOC (including Isopropyl alcohol, n-butyl alcohol, Ethanol, Methylethyl ketone) and Phosphoric acid arepresent in an insignificant amount and within the OES limit.

�@

�@

A note on the quoted OES listed in the above table

|

The objective of this regulation is to prevent disease at workplace due to exposure of hazardous substances. �@ |

�@

�@

�@

| ���� OEL �з� | |

| �@ |

�@ |

�@

| �����a�з� GB/T 16157-1996 | ||

| �@ |

�@ |

|

|

�@ �@ |

�@ |

|

||

|

�@ �@ |

||||

| �@ �@ |

||||

| �@ | �@ | �@ | �@ | |

| �@ | �@ | �@ | �@ | |

| �@ | �@ �@ |

�@ | �@ |

�@

�@

�@

�@