|

|

����Q�����u�~�������q |

|

HONG KONG SPRAYING AND MACHINERY INDUSTRIAL CO. LTD.

|

�@

�@

| PRODUCT |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

�@

| HONG KONG OFFICE |

| Address: No 7-8, 11/F Block A, Vigor Industrial Building, 14-20 Cheung Tat Road, Tsing Yi |

| �@ |

| Tel: 24317981 |

| Fax: 24320126 |

| �@ |

| E-mail: sales@hkspraying.com.hk |

| PRODUCT | CONTACT | ���� |

�@

| EYE FRAME SPRAY BOOTH | �@ |

�@

| Filtering principle | ||

|

�@ �@ |

1. By use of ��Negative Pressure�� to attract overspray 2. When the exhausting fan of the booth is turned on, a strong ��Negative Pressure�� will be created to attract the overspray. Overspray & water mixture will be co-entrained into the booth by the high velocity of air flow created by the fan. An extreme turbulence as ��Tornado Effect�� will be formed to scrub the overspray in the washing tank. Only exhausted gas will flow outside �V so it can nearly 100% wash away the overspray. �@ |

�@

�@ |

�@

| Advantages | ||

| �@ |

Any uncaptured overspray (VOC and phosphoric acid) will be present in an

insignificant amount and within the OEL set by the Labour Department of Hong

Kong�@ �@

|

�@

�@ |

EYE

FRAMES SPRAY BOOTH

-------------------------------------------------------------------------

�@

| PLASTIC & METAL EYE FRAME SPRAY BOOTH | |||

|

�@ �@ |

�@ 1. frame rotation speed and gun movement (both direction & speed) are adjustable on all axes 2. entirely made of stainless steel 3. equipped with 2 automatic spray guns 4. capacity of pieces holder rack: 18 frames 5. production rate: 800-1200 frames per hour 6. External overall dimension: LxWxH = 2000x1410x2620mm

|

||

|

�@

�@ |

|

|

|

|

�@

�@ |

�@ | �@ | |

�@

�@

| METAL EYE FRAME SPRAY BOOTH | |||

|

�@ �@ |

�@ 1. frame rotation speed and spray angle can be adjustable for even coating 2. equipped with spray gun holder for ��Graco�� automatic electro-static gun (gun is not included) 3. suitable for watch and small accessories spraying 4. capacity of pieces holder rack: 18 frames 5. production rate: 800-1200 frames per hour 6. Working area dimension: LxWxH = 1950x1800x1300mm �@ |

||

|

�@ �@ |

|

|

|

|

�@

�@ |

�@ | �@ | |

�@

�@

�@

| RACK ROTATION CABINET | |||

|

�@ �@ |

�@ 1. coated frames should be allowed for rotation in the Rack Rotation Cabinet immediately after coating and before drying in the static oven2. with the Rotation, formation of drops can be avoided and the fresh varnish remains smooth on the surface of the frames 3. Features: a. can hold 10 racks of coated frames b. rotation time: 3-6 minutes c. dimension: LxWxH = 1200x550x1700mm �@ |

||

|

�@ �@ |

|

|

|

| �@ | �@ | �@ | |

�@

�@

| STATIC OVEN FOR FRAME DRYING | |||

|

�@ �@ |

�@ 1. Heating by convention "horizontal hot air circulation" & equipped with "interlock hot air supply" to avoid the risk of sudden temperature rise

2.

Oven

temperature: ambient to 220�J,

thermostatic,

self-timing with explosion proof window and

fresh air supply by convention

3.

Perfect insulation: oven outside

temperature is less than 40�J, so

heat loss can be minimized

4.

Control panel composed of: master

switch, thermostatic, automatic drying timer with

alarm, indication lights and

explosion-proof window �@ |

||

|

�@ �@ |

|

|

|

�@

�@

�@

���۰ʲ���[�Q����

-------------------------------------------------------------------------

�@

| �B�@��z | ||

|

�@ �@ |

�@

���Q�����Q�� "�t�����O"

��z�M�~����,��l�L�Q����P���V�X, ���Ϥ������������� "�s����"

�ĪG�ӹ����M�~���o�o��,���o���d�������,�Q�������Ů�h�ƥX�ǥ~,

�ҥH�����A�X�����c��������[�Q������.

�@ |

|

�@

| �u�I | ||

| �@ | ���Q�����ŦX����Ҥu�B�W�w���o���̰��i�Ʃ�q�з� (OEL), �]�Ӧ�������[�Q���ɫ��w�ϥΪ��Q����. |

|

�@

| �@ | �@ | �@ | �@ |

| �@ �@ |

�@ | �@ | �@ |

�@

�@

�@

�콦�Ϊ��ݲ���[�Q����

-------------------------------------------------------------------------

�@

| �L�o��z | ||||

| �@ |

1. ��ر��ਤ��,

�Q�j�n�\���פμQ�����Ƨ��i�ۥѽծ�, �O���������� 2. �����ĥΤ����s�y 3. �t�Ʀ۰ʮ�Q�j, �Ͳ��IJv��, �C�p�ɲ��q�F 80 ����� 4. �i�Q��Ӥp�����콦�s��ο��� �@ |

|||

|

�@ |

|

|

|

|

�@

�@

�@

���ݲ���[�Q����

-------------------------------------------------------------------------

�@

| �u�I | |

| �@ |

1. ��ر��ਤ�ץi�ۥѽծ�, �Q�j�n�\���פμQ�����Ƨ��i�ۥѽծ�, �O���������� �@ 2 . �i��Φ۰ʮ�Q���j�Φ۰��R�q�Q���j, �Ͳ��IJv��, �C�p�ɲ��q�F 80 ������@ 3. �i�Q��Ӥp�����콦�s��ο���

|

| �@ �@ |

|

|

|

| �@ �@ |

�@

|

�@ | �@ |

�@

�@

����[�y����

-------------------------------------------------------------------------

| �@ �@ |

�@ 1. ����[�Q����J�K�l�e����y����������H�O����ح��o�����ƫG�R 2. �i�P���\�� 10 ����� 3. �j�ਤ��, ��V�ήɶ����i�ۥѽծ� �@ |

�@

| �@ | �@ | �@ | �@ |

| �@ | �@ | �@ | �@ |

| �@ | �@ | �@ | �@ |

| �@ | �@ | �@ | �@ |

| �@ | �@ | �@ | �@ |

| �@ | �@ | �@ | �@ |

| �@ | �@ | �@ | �@ |

| �@ | �@ | �@ | �@ |

| �@ | �@ �@ �@ |

�@ | �@ |

�@

�@

�@

�@

�@

�o����ղŦX�^��,����Τ����a�з�

-------------------------------------------------------------------------

�@

| �^�� OES �з� | |

| �@ |

�@ 1. �Ĥ@�Ӽo��˥��t�зǼQ�@��� 2. �ĤG�Ӽo��˥��ߨ������Q�@��� |

|

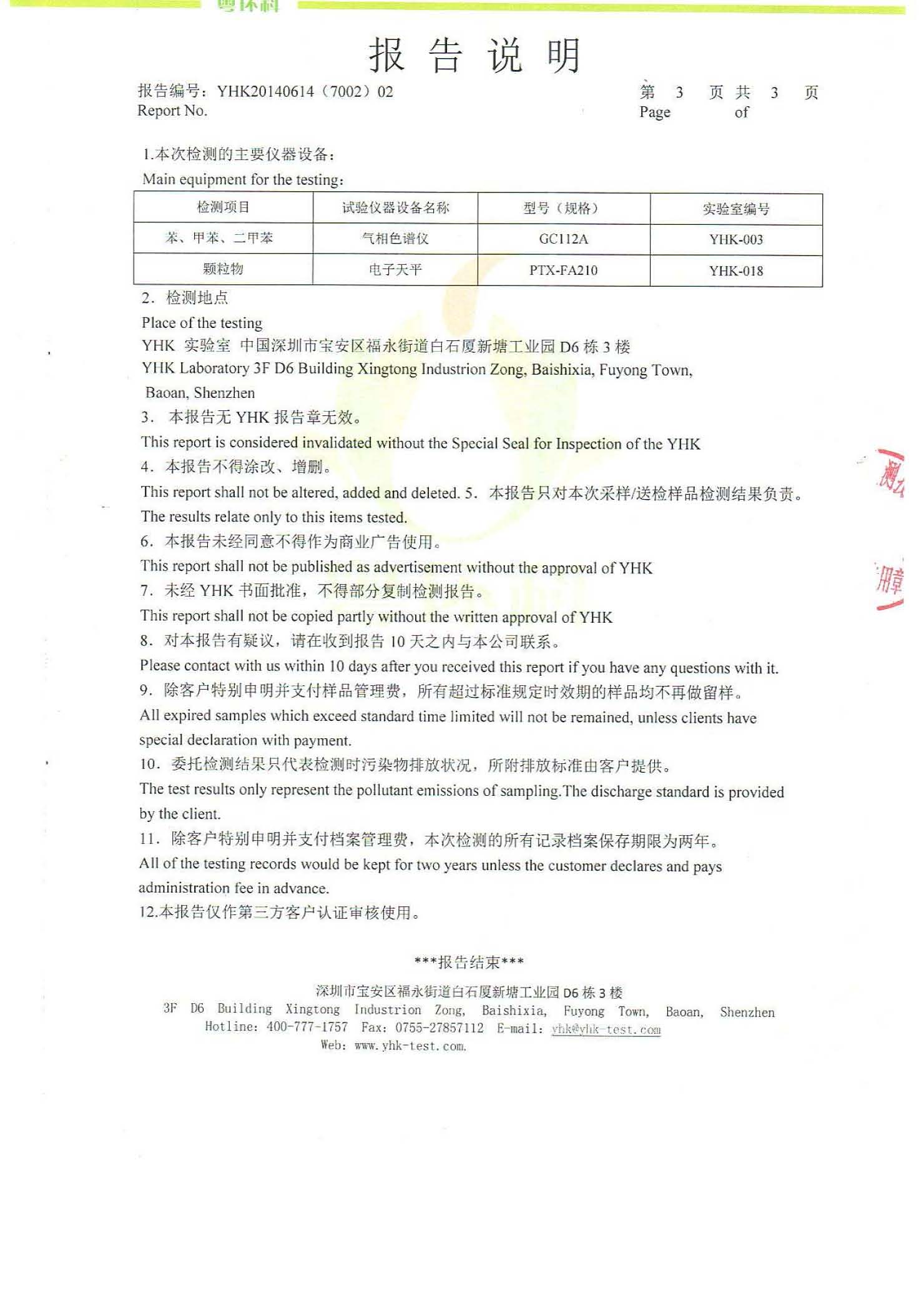

COMPONENT VOC |

OES Limit | Sampling with standard Water-Wash Spray Booth (Shenzhen: 7/1/98) |

Sampling with Specially made Water-Wash Spray Booth (Chek Lap Kok:30/7/98) |

|

Isopropyl alcohol �@ |

400ppm | <0.1ppm | <0.1ppm |

|

n-butyl alcohol �@ |

50ppm | <0.1ppm | <0.1ppm |

|

Ethanol �@ |

200ppm �@ |

0.5ppm �@ |

<0.1ppm |

| Methylethyl ketone | 1000ppm | 6.8ppm | 2.8ppm |

| Phosphoric acid | 1mg/m3 | 0.2mg/m3 | <0.05mg/m3 |

�@

Conclusion

The concentrations of five different parameters in the paint mist were measured at Shenzhen (7-1-98) and Chek Lap Kok (30-7-98) respectively and the results are presented. It is concluded that the VOC (including Isopropyl alcohol, n-butyl alcohol, Ethanol, Methylethyl ketone) and Phosphoric acid arepresent in an insignificant amount and within the OES limit.

�@

�@

A note on the quoted OES listed in the above table

|

The objective of this regulation is to prevent disease at workplace due to exposure of hazardous substances. �@ |

�@

�@

�@

| ���� OEL �з� | |

| �@ |

�@ |

�@

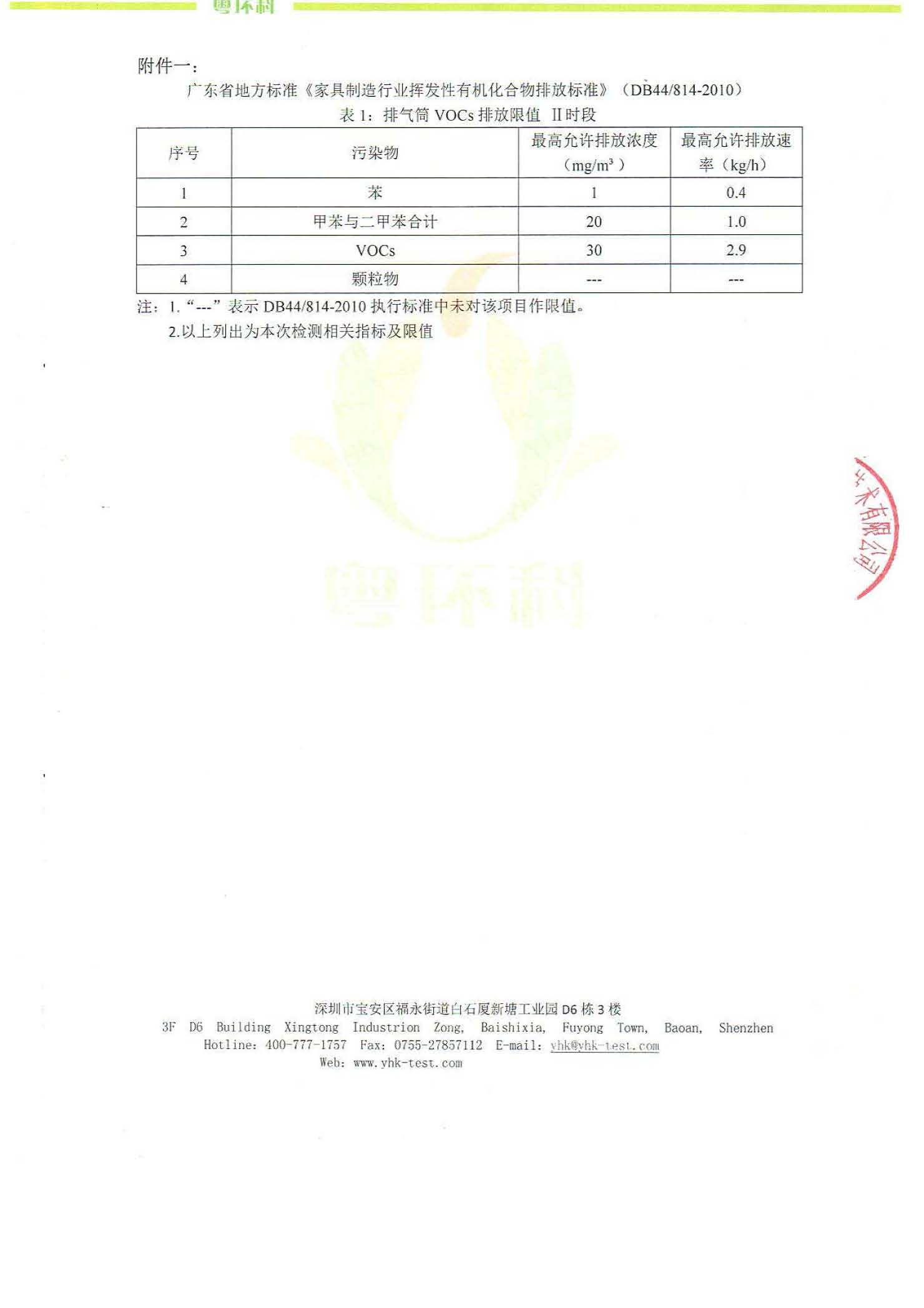

| �����a�з� GB/T 16157-1996 | ||

| �@ |

�@ |

|

|

�@ �@ |

�@ |

|

||

|

�@ �@ |

||||

| �@ �@ |

||||

| �@ | �@ | �@ | �@ | |

| �@ | �@ | �@ | �@ | |

| �@ | �@ �@ |

�@ | �@ |

�@

�@

�@

�@