|

|

香港噴塗機械工業有限公司 |

|

HONG KONG SPRAYING AND MACHINERY INDUSTRIAL CO. LTD.

|

| PRODUCT |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| HONG KONG OFFICE |

| Address: No 7-8, 11/F Block A, Vigor Industrial Building, 14-20 Cheung Tat Road, Tsing Yi |

| Tel: 24317981 |

| Fax: 24320126 |

| E-mail: sales@hkspraying.com.hk |

| PRODUCT | CONTACT | 中文 |

| Spray Booth |

Requirement of the Law for the design of a Spray

Booth

-------------------------------------------------------------------------

|

|

According to the Factories & Industrial Undertakings (Spraying of flammable liquids) Regulations (s59N) of the Labour Department of Hong Kong a spray room or spraying area, including any spray booth or cabinet, where flammable liquid spraying process is carried out must be efficiently ventilated to open air by mechanical means so as to remove any flammable vapour, mist or spray arising from the spraying process. Good ventilation is essential to control the hazards from spraying process which has two main functions, namely: (a) to carry off and disperse the overspray and (b) to reduce the concentration of flammable vapour in air by dilution to below the explosive level

For 1994 version of s59N, regulation 5.6-5.8 further stipulates that: In a conventional cabinet-type spray booth, an air velocity of not less than 30 metres per minute (i.e. 0.5 metre/second) into the open frontal area of the booth is sufficient for vapour removal The shallower the booth, the higher must be the face velocity because of rebound of the sprayed material from the work and from the back and sides of the booth. The duct opening of shallow booths should be at the rear and dully baffled to prevent direct spray from entering the pipe

For 1997 version of s59N, regulation 5 does not specify the air velocity for vapour removal, regulation 5 stipulates: Where a flammable liquid spraying process is carried out, either in a spraying room or a spraying area, including in the case of a spraying area any booth or cabinet within such area, shall be efficiently ventilated to open air by mechanical means adequate to remove from any such room, area, booth or cabinet any flammable vapour, mist or spray arising from the spraying process.

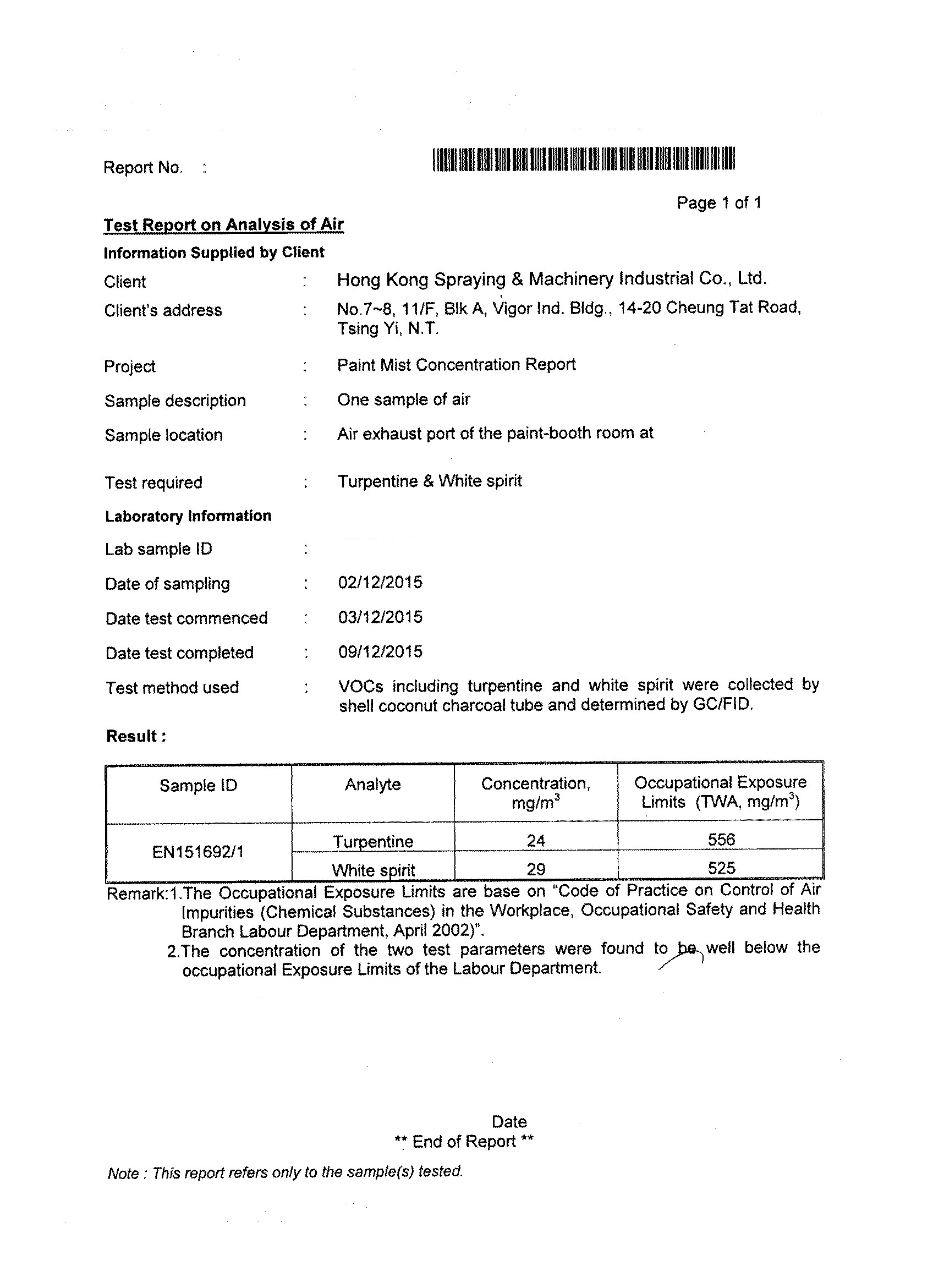

Requirement of the Law for the paint mist concentration According to the Code of Practice on control of Air Impurities (Chemical Substances) in the Workplace (version 2002) of the Labour Department of Hong Kong, proprietors are required to assess the health risks due to the exposure of the workers to the chemical substances commonly found in the workplace and take adequate measures to safeguard the workers against air impurities. Air impurities in the workplace should be within the Occupational Exposure Limits for Chemical Substances in the Work Environment.

|

DRY FILTER

SPRAY BOOTH

-------------------------------------------------------------------------

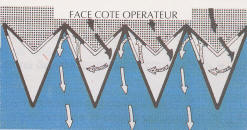

| Filtering principle | |||

|

|

There is a fan drawing overspray into a paper filter pleated with many “V” pleats at the back of the booth, thus, overspray resins will be collected and clean air is allowed to be exhausted without dropping vital air flow below the prescribed limits. The retention capacity of the pleated filter is up to 25 kg/m2 , filtering efficiency is up to 98.5%. A fibreglass filter is added at back of the pleated filter to increase the paint retention capacity.

|

||

|

|

|

|

| Advantages | ||

|

Water-curtain spray booth (as no water pump is required and only a smaller KW motor is required) very suitable for spraying large or hanging objects

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

"Water Curtain

Spray Booth" (with pump)

-------------------------------------------------------------------------

| Filtering principle | ||

|

There is a vertical water-screen to catch overspray and carry it down into a washing tank that is located on the bottom of the booth. The washing tank contains water mixture which can break down sticky overspray resins. The broken-down resins will be collected in this tank. However, efficiency of the screen depends on the function of its circulating pump, nozzles, pipework and filters which heavily depends on the type of paints you use.

|

|

|

| Advantages | ||

|

If water-based paints are used, then the booth can work efficiently as no clogging occurs |

|

|

| Disdvantages | ||

|

1. Clogging will occur if non-water based paints are used. Clogging in the filtering system occurs because sticky paints will enter the pump, nozzles, pipework and filters.

2. Shocking will result due to the rough running of the filtering system out of clogging. The booth’s efficiency will thus be diminished and eventually it ceases to operate.

|

|

|

|

|

||

|

|

||

| Applications | |

|

This spray booth is only suitable for small-batch production

|

|

"Water

Wash

Spray Booth" (without pump)

-------------------------------------------------------------------------

| Filtering principle | |

|

This booth only requires a fan which creates a high velocity of air flow across the surface of the water tank. Overspray and water & oil mixture will be co-entrained into the booth filter by the strong air which will then form an extreme turbulence as “Tornado Effect” to scrub the overspray in the washing tank. Due to the functions of water and mineral oil, each resin particle will immediately receive an oil coating and is distributed scatteredly. The coating is renewed as recirculation of the particles causes them to pass through the oil film again.

|

|

| Advantages | |

|

This booth can solve the problem of Water-Screen Spray booth because it uses the “No-Pump Principle”- no water screen and no pump. By filling in some mineral oil (about 0.5” height in the water tank) and then pour enough water (at the marked level of the water tank) into the water tank, the filtering system is ready to function.

The resin particles will eventually sink onto the bottom of the washing tank as a non-sticky silt which is relatively easy to dispose of. Since no pump is required, no clogging in the filtering system will occur, filtering efficiency can be guaranteed.

|

|

Comparison between water-wash spray booth &

water-curtain spray booth

-------------------------------------------------------------------------

|

|

Water-Wash Spray Booth (No Pump) |

Water-curtain Spray Booth (with Pump) |

| PRINCIPLE OF OPERATION |

When the exhausting fan of the booth is switched on, a strong "Negative Pressure" will be created to attract the overspray.

Overspray and water mixture will be co-entrained into the booth by the high velocity of air flow created by the fan.

An extreme turbulence as "Tornado Effect" is formed to scrub the the overspray in the washing tank. Only exhausted gas will flow outside - so it can nearly 100% wash away the overspray. Any uncaptured overspray (VOC) will only present in an insignificant amount and within the OEL set by the Labour Department of HK. |

By use of

a water circulating pump, overspray can be

washed away via water pipe, water screen plate

and water nozzle. As there are gaps between

nozzles, overspray cannot be washed away totally

(especially when the booth is equipped with

multi-layered water screen plates or with

shorter nozzle cleaning path).

Overspray and exhausted gas will be allowed to flow outside. |

| EXHAUSTING FAN | Use specially-designed exhausting fan (for spray use only), medium pressure, large exhausting flow rate, so no overspray will stick onto the fan, and thus shocking will not be resulted | Use non-specially-designed exhausting fan, many overspray will stick onto the fan and shocking will be resulted |

| CIRCULATING PUMP |

1. Not required as no clogging will occur

2. No water screen means no water rebounds (due to small pieces of paint sludge formed in front of the water screen), so the object will not get water spots on it. |

1. As water pump is required, sticky paint will enter into the circulating pump, nozzles, pipework, so clogging will occur. Shocking will be resulted due to the rough running of the filtering system out of clogging. As a result, the exhausting fan will require a thorough clean-up service as shocking occurs

2. As overspray enters into the water pump, nozzles, pipework, small pieces of paint sludge will from in front of the water screen, and the object will get water spots on it, especially during peak spraying period. |

| CLEAN UP |

By filling in adequate water and mineral oil,

paint sludge will float onto the surface of the

water tank.

Clean up once a week or even a month is adequate.

|

Paint

sludge will deposit onto the nozzles and mesh,

so clean up process is required for several

times a day.

Even double layers of stainless steel mesh cannot help much in this matter. |

| MAINTENANCE |

No repair is required - we have 5 years of

guarantee.

|

High cost of doing a

proper clean-up If clean-up is improper or heavy spraying duty is required, shocking will be resulted due to rough running of the filtering system out of clogging. Booth efficiency will thus be diminished and eventually it ceases to operate.

|

| TARGET FOR | Heavy spraying duty | Sample spraying or light spraying duty |

| MANUFACTURER | Hong Kong Spraying & Machinery Industrial Co Ltd | Non-specialized spraying equipment manufacturers or electrical oven manufacturers |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Air sampling tests meet the requirement of UK, HK &

China

-------------------------------------------------------------------------

| UK OES | |

|

1. the first sample taken from our standard booth 2. the second sample taken from Chek Lap Kok |

|

|

COMPONENT VOC |

OES Limit | Sampling with standard Water-Wash Spray Booth (Shenzhen: 7/1/98) |

Sampling with Specially made Water-Wash Spray Booth (Chek Lap Kok:30/7/98) |

|

Isopropyl alcohol

|

400ppm | <0.1ppm | <0.1ppm |

|

n-butyl alcohol

|

50ppm | <0.1ppm | <0.1ppm |

|

Ethanol

|

200ppm

|

0.5ppm

|

<0.1ppm |

| Methylethyl ketone | 1000ppm | 6.8ppm | 2.8ppm |

| Phosphoric acid | 1mg/m3 | 0.2mg/m3 | <0.05mg/m3 |

Conclusion

The concentrations of five different parameters in the paint mist were measured at Shenzhen (7-1-98) and Chek Lap Kok (30-7-98) respectively and the results are presented. It is concluded that the VOC (including Isopropyl alcohol, n-butyl alcohol, Ethanol, Methylethyl ketone) and Phosphoric acid arepresent in an insignificant amount and within the OES limit.

A note on the quoted OES listed in the above table

|

The objective of this regulation is to prevent disease at workplace due to exposure of hazardous substances.

|

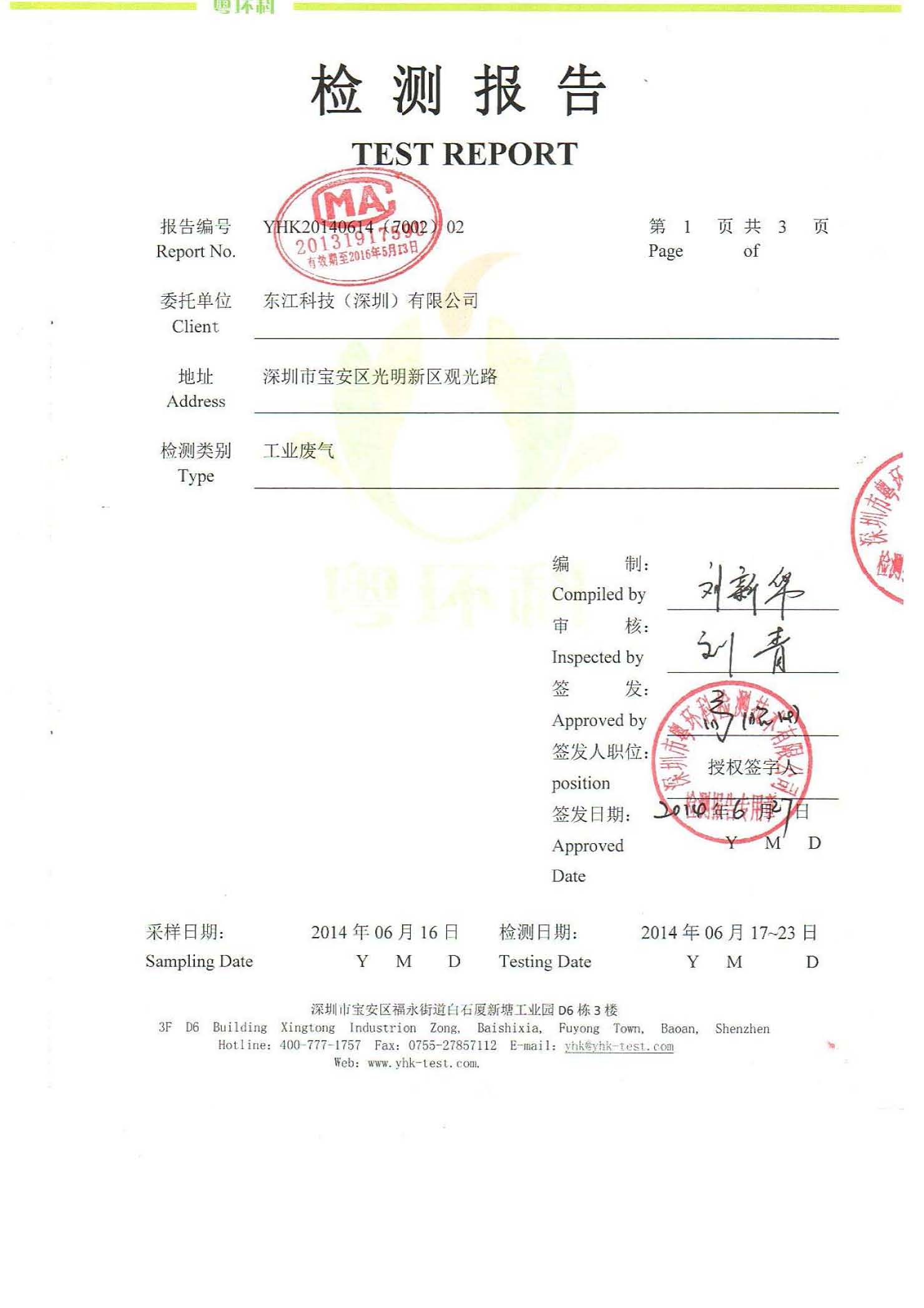

| Hong Kong OEL | |

|

|

|

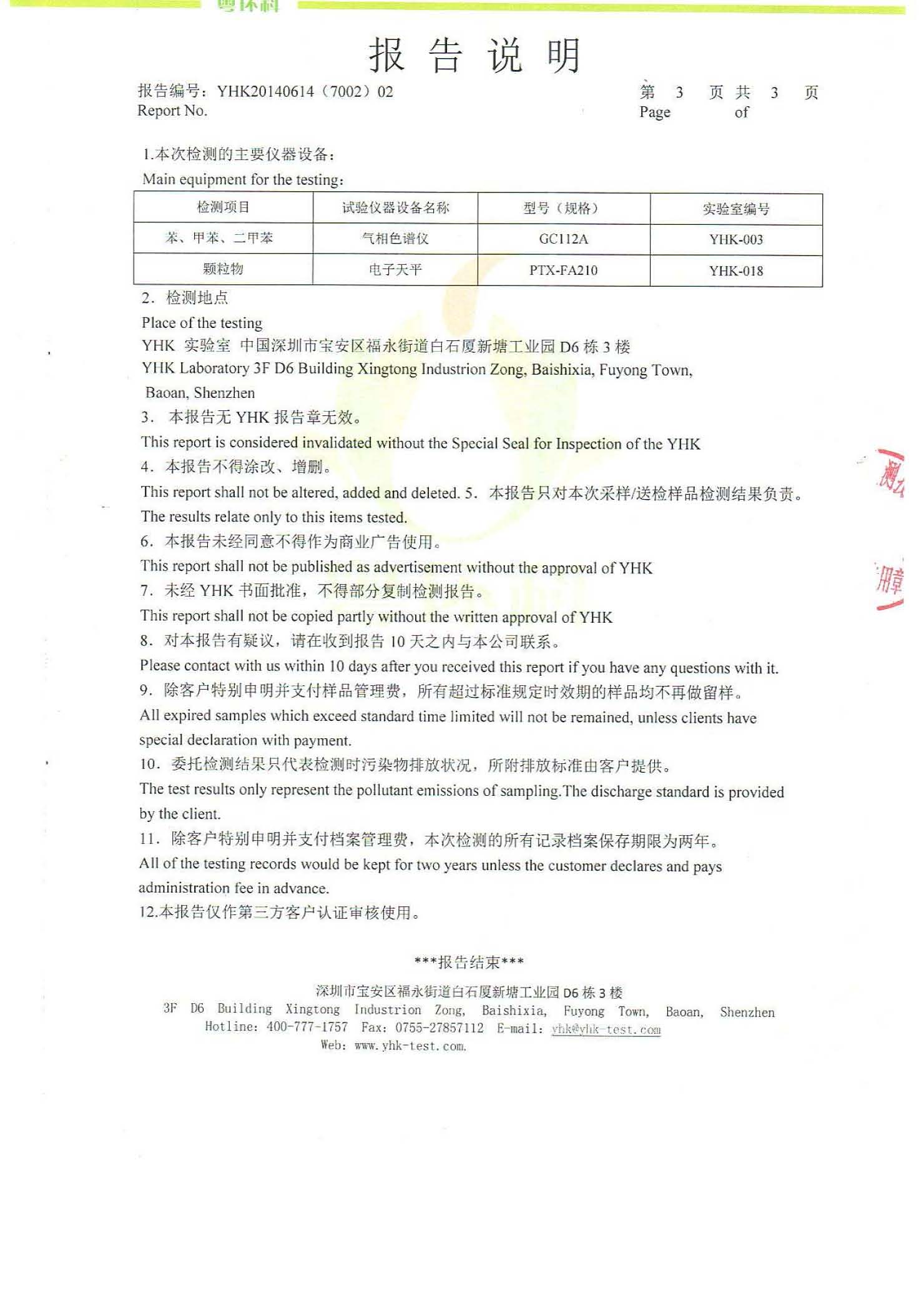

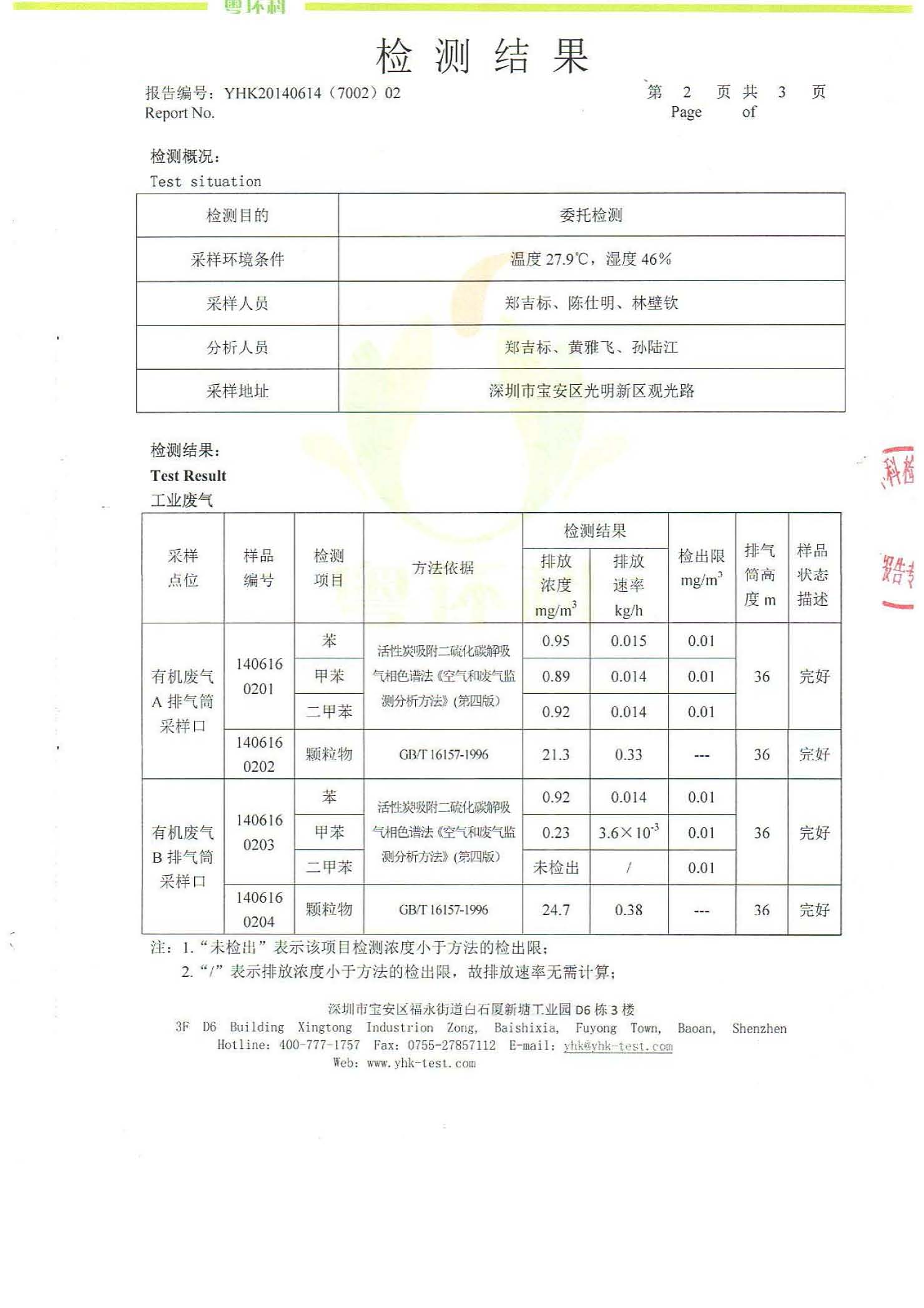

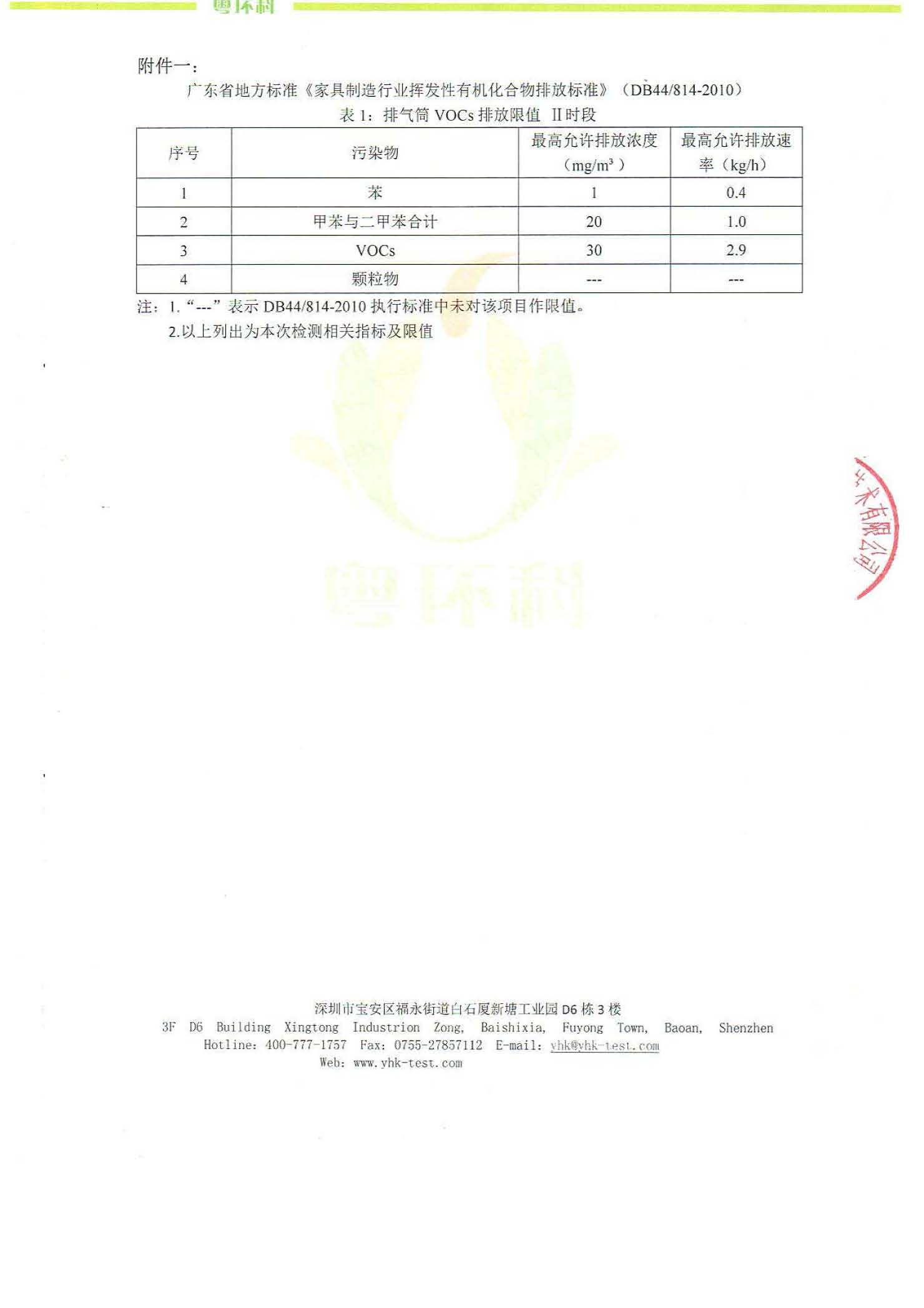

| China GB/T 16157-1996 | ||

|

|

|

|

|

|

|

|

||

|

|

||||

|

|

||||

|

|