|

|

����Q�����u�~�������q |

|

HONG KONG SPRAYING AND MACHINERY INDUSTRIAL CO. LTD.

|

�@

�@

| PRODUCT |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

�@

| HONG KONG OFFICE |

| Address: No 7-8, 11/F Block A, Vigor Industrial Building, 14-20 Cheung Tat Road, Tsing Yi |

| �@ |

| Tel: 24317981 |

| Fax: 24320126 |

| �@ |

| E-mail: sales@hkspraying.com.hk |

| PRODUCT | CONTACT | ���� |

�@

| OVEN | �@ |

�@

�@

METHODS

FOR CURING

------------------------------------------------------------------------

�@

| AIR DRYING | |

|

�@ �@ |

PRINCIPLE OF OPERATION Paints get cured under room temperature as 1. volatile thinner evaporates and paints become dried 2. dry thinner oxides as a film by oxidizing polymers 3. hardening paints get hardened by hardeners in paints �@ DRAWBACK a. high humidity makes violate thinners harder to evaporate and poor paint film quality is resulted (discoloured or dusty paint film). Air-conditioners and dust filtering system are required to improve paint film quality. b. high room temperature can make paints easier to evaporate, less dust on paint film but poor flash-off �@ |

�@

| CURING BY HEATING | |||

| �@ |

�@ Curing oven can be divided into 3 types 1. Low temperature oven oven temperature: <100�J, it is used to speed up the curing time of self-cured paints 2. Medium temperature oven oven temperature: 100-150�J, it is used to cure paints that require condensation reaction or polymerization oven temperature should not be >150�J, otherwise, coating will get yellowing and brittle 3. High temperature oven oven temperature: >150�J, it is used for powder coating or electrophoretic coating �@ |

||

|

�@

�@ |

|

|

|

HEATING

METHODS FOR CURING OVEN

------------------------------------------------------------------------

�@

| CONDUCTION & CONVENTION HEATING (HOT AIR OVEN) | ||

|

�@ �@ |

�@ PRINCIPLE OF OPERATION Heating with gas or liquid to: 1. by conduction: transfer heat from the heating tubes to the paint substrates with gas or diesel 2. by conduction & convention: transfer heated gas to the paint substrates

|

|

|

ADVANTAGE Hot gas circulates evenly in the oven to a. make objects evenly cured, even for objects with recessed areas b. speed up paints volatile �@ |

|

|

|

DISADVANTAGE a. Hot gas oven heats up objects from outside to inside, which results in: low rising temperature, low heat transfer efficiency, high power consumption, long oven size, high dust prevention requirement b. (outside) coating cures first than the inside part so pimples or bubble marks will easily deposit on the coating surface �@ |

||

�@

�@

| STATIC OVEN & TUNNEL OVEN | |||

|

�@ �@ |

�@ 1. Heating by convention "horizontal hot air circulation" & equipped with "interlock hot air supply" to avoid the risk of sudden temperature rise

2.

Oven

temperature: ambient to 220�J,

thermostatic, self-timing with explosion proof

window

3.

Perfect insulation: oven outside

temperature is less than 40�J, so

heat loss can be minimized

4.

Control panel composed of: master

switch, thermostatic, automatic drying timer with

alarm, indication lights and

explosion-proof window �@ �@ |

||

|

�@ �@ |

|

|

|

|

�@ �@ |

|

|

|

�@

�@

�@

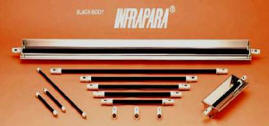

| RADIATION HEATING (INFRARED OVEN ) | |

|

�@ �@ |

�@ 3 WAVELENGTHS OF INFRARED OVEN 1. Near infrared (short wave): wavelength: 0.75-2.5�gm radiator temperature: 2000-2200�Jradiation efficiency: high �@ 2. Medium infrared (medium wave): wavelength: 2.6-4.0�gm radiator temperature: 800-900�Jradiation efficiency: medium �@ 3. Far infrared (long wave): wavelength: >4.0�gm radiator temperature: 400-600�Jradiation efficiency: low �@ |

�@

�@

| CURING PRINCIPLE | |||

|

�@ �@ |

1. when the wavelengths of infrared match with that of the vibration of paint molecules, paint molecules can absorb the infrared and the paint will be cured, otherwise, the objected can only be heated and cured by the evaporation of thinner inside 2. as the wavelengths of the vibration of paint or water molecules is normally >4.0�gm, we need to heat up the inner part of the object by near infrared (short wave) and cure the coating by far infrared (long wave) 3. distance between the infrared reflector and the object should be 120-300mm, otherwise radiation efficiency will be adversely affected �@ |

||

| �@ | �@ | �@ | |

�@

�@

| ADVANTAGE | ||

|

�@ �@ |

�@ As object is cured from inner to outside coating by infrared oven which means the object and coating is heated at the same time which will result in a a. higher rising temperature, higher heat transfer efficiency, lower power consumptionb. faster thinner evaporation, better coating quality, shorter oven size, lower dust prevention requirement�@ �@ |

|

�@

�@

| DISADVANTAGE | |||

|

�@ �@ |

�@ |

�@ 1. uneven oven temperature in infrared oven means different curing speed for objects with different shapes; so infrared lamp panel is more suitable for objects with different shapes �@ 2. as water molecules can absorb infrared, blower is required to blow away water molecules in order to speed up thinner evaporation �@ |

�@

�@ |

�@

�@

DIFFERENT

INFRARED CERAMIC HEATERS

------------------------------------------------------------------------

�@

| Infrared heating plate | |||

|

�@ �@ |

�@ |

�@ 1. radiant ray is parallel to its horizontal ray and diffusion ray, this plane is suitable to cure plane objects because of even heat distribution 2. poor heat transfer on the back of the heating plate �@ �@ �@ �@ |

|

|

|

|||

�@

�@

| Infrared heating lamp | |||

| �@ | �@ |

�@ a. is less affected by radiant distance, smallest temperature difference for radiant distance of 200-600mm, so it is suitable for complex objects with different sizes �@ �@ �@ |

|

|

�@ �@ |

�@ |

�@ |

|

�@

�@

| Infrared heating tube | |||

|

�@ �@ |

�@ |

�@ a. made of ceramics, insulation layer in the middle, outside coated with far infrared coating b. as this tube has thin heating layer and does not have resistance wire, heat distribution can be even and there is no visual light loss which can ultimately improve the heat transfer �@ |

|

�@

MIX OF HOT AIR & INFRARED OVEN

------------------------------------------------------------------------

�@

| PRINCIPLE OF OPERATION | |||

|

�@ �@ |

�@ To let thinner out by infrared heating and to keep even oven temperature by hot air convection heating �@ a. as metal can absorb radiant heat energy from infrared heating, therefore, in order to speed up the heating effect, we can get higher oven temperature (above 300 �J) and shorter oven tunnel at the same time �@ b. this oven can maintain a stable oven temperature as there is an air insulation layer in the middle to guarantee the oven outside temperature is less than 40 �J - a good way to minimize heat loss and energy saving �@ c. each section of our tunnel oven is checked with Oven Tracker - to maintain stable oven temperature before delivery �@ |

||

|

�@

�@ |

|

|

|

|

�@

�@ |

|

|

|

�@

�@

�@

| ADVANTAGE | |

|

�@ �@ |

�@ have advantages of both infrared heating and hot air heating: 1. advantage of infrared heating a. fast oven rising temperature b. good coating quality �@ 2. advantage of hot air heating a. even oven temperature: even curing speed for objects of different size b. fast thinner evaporation �@ |

�@

UV OVEN

------------------------------------------------------------------------

�@

| ADVANTAGE | |||

|

�@ �@ |

�@ to cure objects by UV lamps a. short curing time: ideal for paper, plastics or wood coating b. low oven temperature for curing �@ |

||

|

�@ |

|

|

|

�@

| DISADVANTAGE | |

|

�@ �@ |

�@ a. short diffusion distances b. only suitable for simple objects �@ |

���۰ʲ���[�Q����

-------------------------------------------------------------------------

�@

| �B�@��z | ||

|

�@ �@ |

�@

���Q�����Q�� "�t�����O"

��z�M�~����,��l�L�Q����P���V�X, ���Ϥ������������� "�s����"

�ĪG�ӹ����M�~���o�o��,���o���d�������,�Q�������Ů�h�ƥX�ǥ~,

�ҥH�����A�X�����c��������[�Q������.

�@ |

|

�@

| �u�I | ||

| �@ | ���Q�����ŦX����Ҥu�B�W�w���o���̰��i�Ʃ�q�з� (OEL), �]�Ӧ�������[�Q���ɫ��w�ϥΪ��Q����. |

|

�@

| �@ | �@ | �@ | �@ |

| �@ �@ |

�@ | �@ | �@ |

�@

�@

�@

�콦�Ϊ��ݲ���[�Q����

-------------------------------------------------------------------------

�@

| �L�o��z | ||||

| �@ |

1. ��ر��ਤ��,

�Q�j�n�\���פμQ�����Ƨ��i�ۥѽծ�, �O���������� 2. �����ĥΤ����s�y 3. �t�Ʀ۰ʮ�Q�j, �Ͳ��IJv��, �C�p�ɲ��q�F 80 ����� 4. �i�Q��Ӥp�����콦�s��ο��� �@ |

|||

|

�@ |

|

|

|

|

�@

�@

�@

���ݲ���[�Q����

-------------------------------------------------------------------------

�@

| �u�I | |

| �@ |

1. ��ر��ਤ�ץi�ۥѽծ�, �Q�j�n�\���פμQ�����Ƨ��i�ۥѽծ�, �O���������� �@ 2 . �i��Φ۰ʮ�Q���j�Φ۰��R�q�Q���j, �Ͳ��IJv��, �C�p�ɲ��q�F 80 ������@ 3. �i�Q��Ӥp�����콦�s��ο���

|

| �@ �@ |

|

|

|

| �@ �@ |

�@

|

�@ | �@ |

�@

�@

����[�y����

-------------------------------------------------------------------------

| �@ �@ |

�@ 1. ����[�Q����J�K�l�e����y����������H�O����ح��o�����ƫG�R 2. �i�P���\�� 10 ����� 3. �j�ਤ��, ��V�ήɶ����i�ۥѽծ� �@ |

�@

| �@ | �@ | �@ | �@ |

| �@ | �@ | �@ | �@ |

| �@ | �@ | �@ | �@ |

| �@ | �@ | �@ | �@ |

| �@ | �@ | �@ | �@ |

| �@ | �@ | �@ | �@ |

| �@ | �@ | �@ | �@ |

| �@ | �@ | �@ | �@ |

| �@ | �@ �@ �@ |

�@ | �@ |

�@

�@

�@

�@

�@

�o����ղŦX�^��,����Τ����a�з�

-------------------------------------------------------------------------

�@

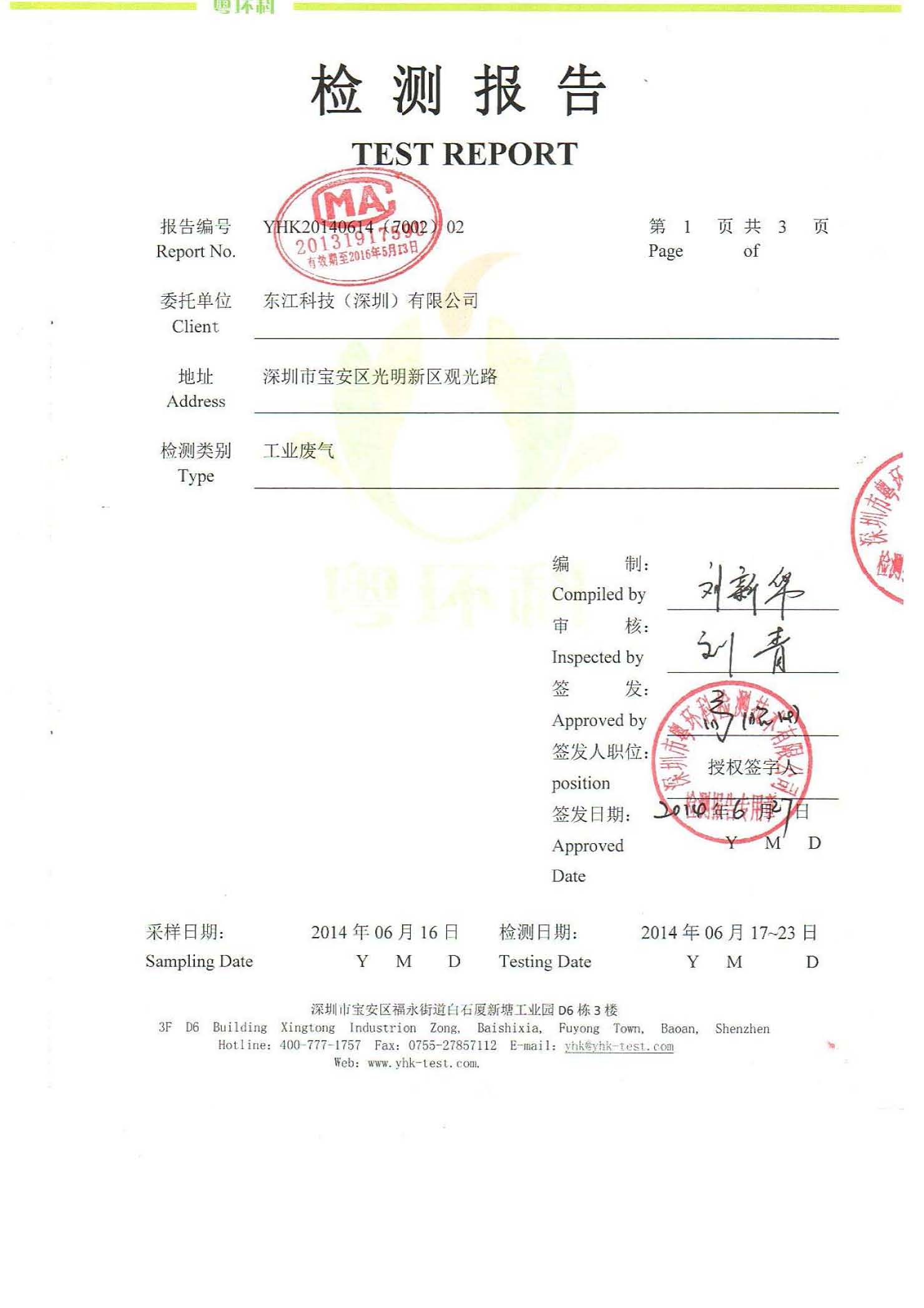

| �^�� OES �з� | |

| �@ |

�@ 1. �Ĥ@�Ӽo��˥��t�зǼQ�@��� 2. �ĤG�Ӽo��˥��ߨ������Q�@��� |

|

COMPONENT VOC |

OES Limit | Sampling with standard Water-Wash Spray Booth (Shenzhen: 7/1/98) |

Sampling with Specially made Water-Wash Spray Booth (Chek Lap Kok:30/7/98) |

|

Isopropyl alcohol �@ |

400ppm | <0.1ppm | <0.1ppm |

|

n-butyl alcohol �@ |

50ppm | <0.1ppm | <0.1ppm |

|

Ethanol �@ |

200ppm �@ |

0.5ppm �@ |

<0.1ppm |

| Methylethyl ketone | 1000ppm | 6.8ppm | 2.8ppm |

| Phosphoric acid | 1mg/m3 | 0.2mg/m3 | <0.05mg/m3 |

�@

Conclusion

The concentrations of five different parameters in the paint mist were measured at Shenzhen (7-1-98) and Chek Lap Kok (30-7-98) respectively and the results are presented. It is concluded that the VOC (including Isopropyl alcohol, n-butyl alcohol, Ethanol, Methylethyl ketone) and Phosphoric acid arepresent in an insignificant amount and within the OES limit.

�@

�@

A note on the quoted OES listed in the above table

|

The objective of this regulation is to prevent disease at workplace due to exposure of hazardous substances. �@ |

�@

�@

�@

| ���� OEL �з� | |

| �@ |

�@ |

�@

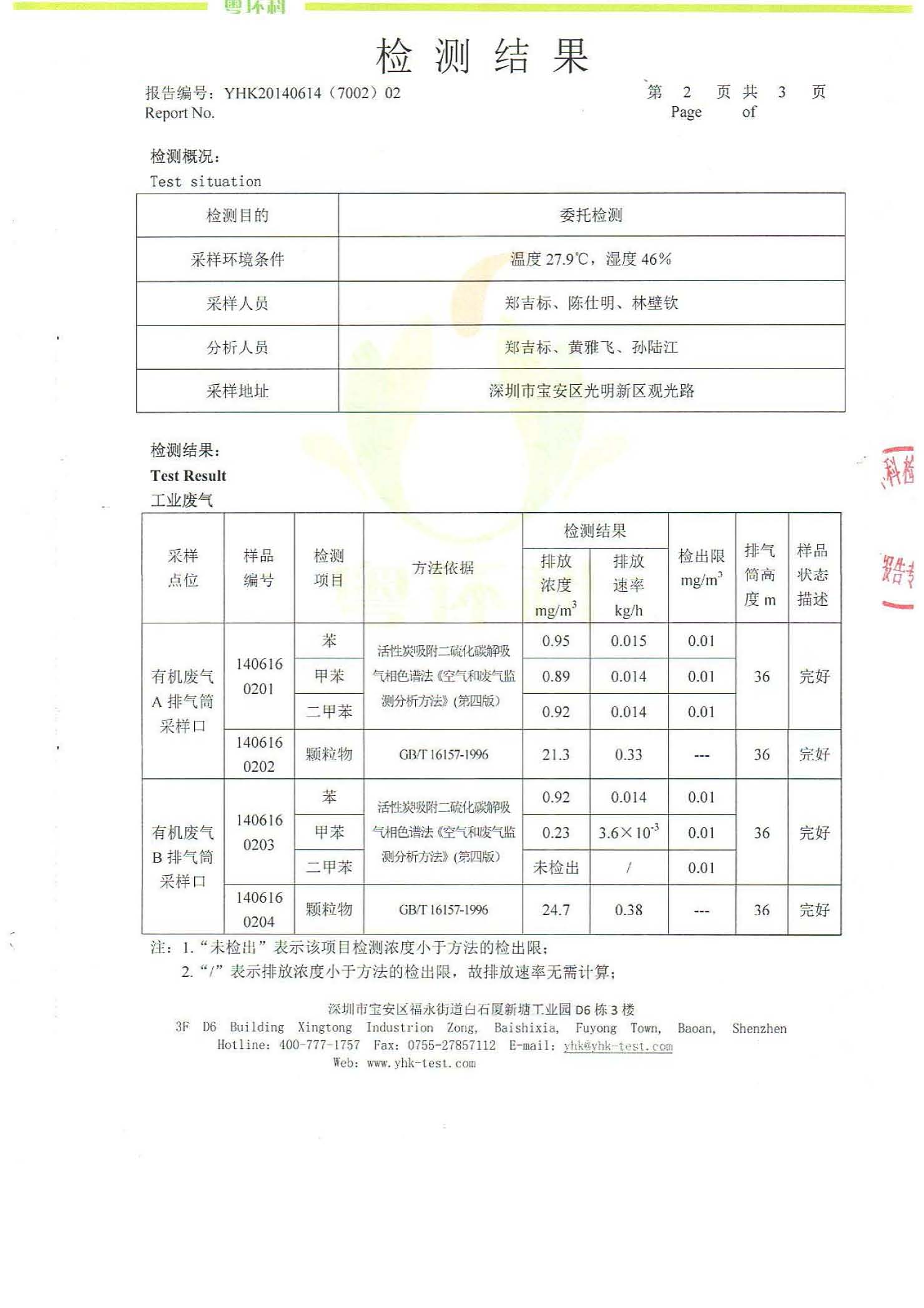

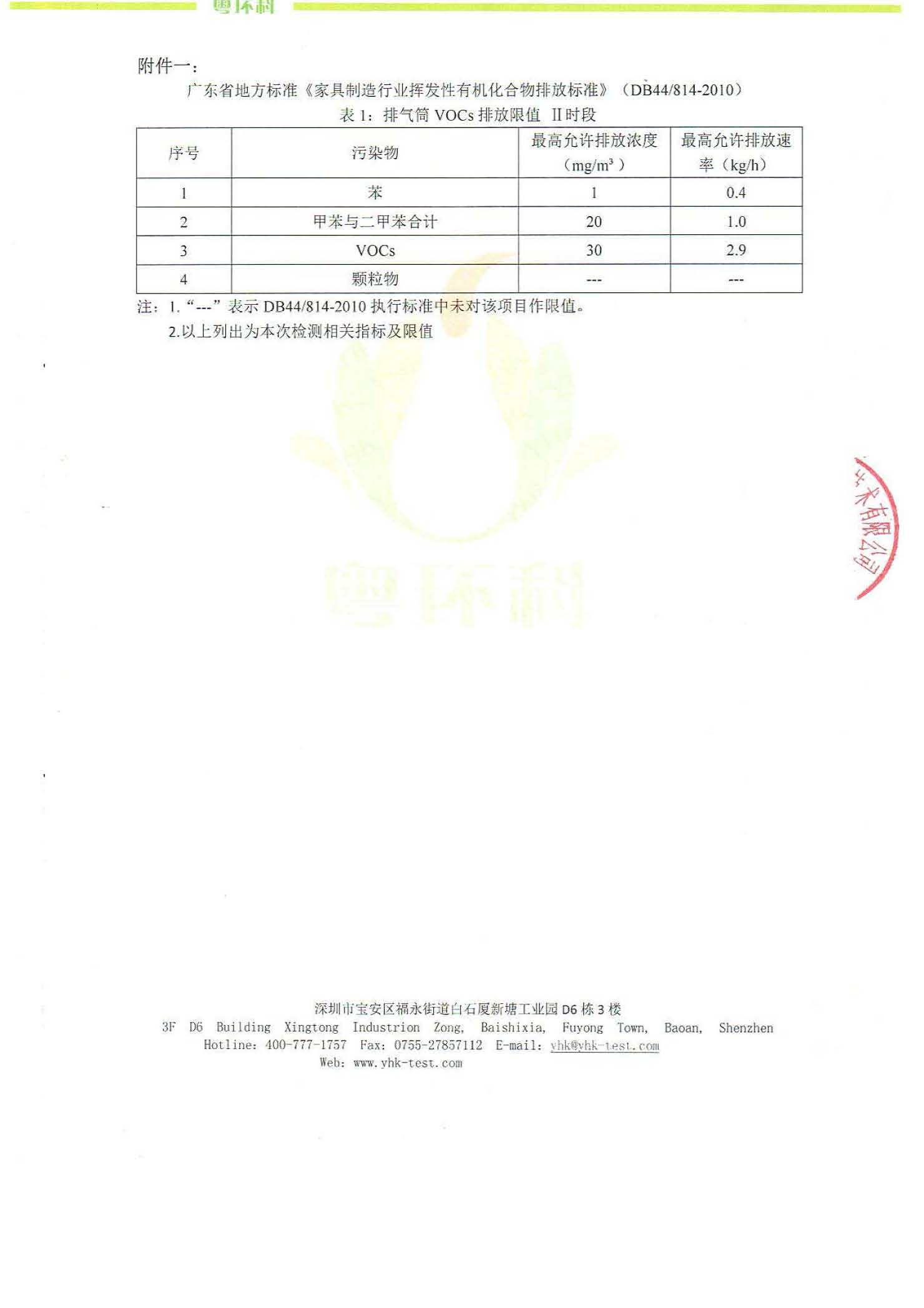

| �����a�з� GB/T 16157-1996 | ||

| �@ |

�@ |

|

|

�@ �@ |

�@ |

|

||

|

�@ �@ |

||||

| �@ �@ |

||||

| �@ | �@ | �@ | �@ | |

| �@ | �@ | �@ | �@ | |

| �@ | �@ �@ |

�@ | �@ |

�@

�@

�@

�@